- Accueil

- Louis Vuitton

- Modeles

- Toiles

- Serrures

- Lozines

- Etiquettes

- Séries

- Expertise

- Prix du neuf

- Record enchère

- Stars LV

- Contrefaçon

- Nouveauté 2024

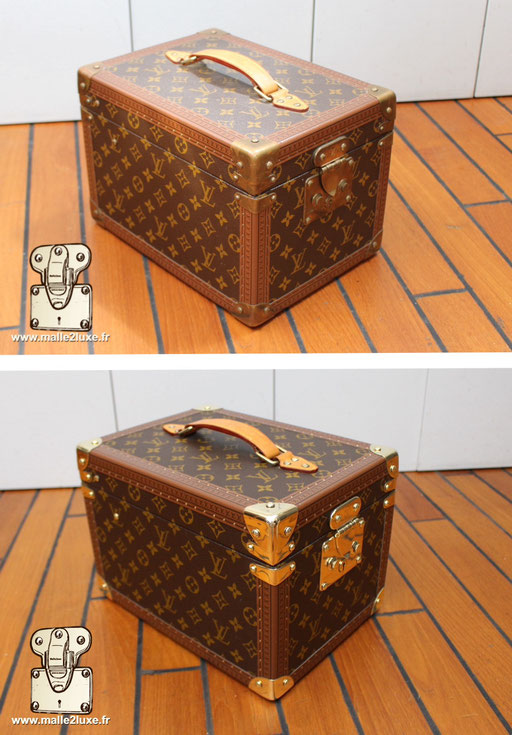

- Vanity

- Valise

- Cabine

- Courrier

- Wardrobe

- Automobile

- Fourrure

- Chaussures

- Ideale

- Aluminium

- Explorateur

- Malle à fleurs

- Cadeau VIP

- Jouets

- Chapeau

- Leopold Stokowski

- Albert Kahn

- Tableau

- Lit

- Tiroirs

- Bibliotheque

- Aéro

- Cigare

- Pique-nique

- Alcool

- Pêche

- Marmotte

- Steamer Bag

- Vermeer

- Vendôme

- Georges Vuitton

- Gaston Vuitton

- Homme cible

- Sac petite malle

- Goyard

- Moynat

- Hermès

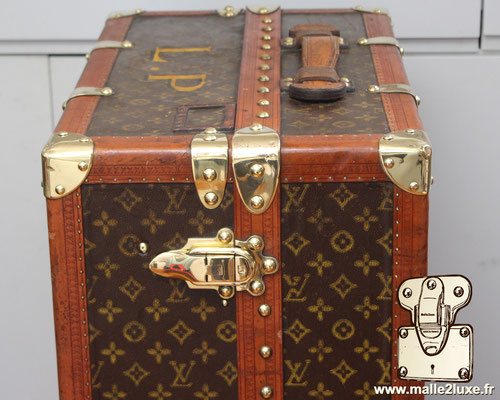

- Pièces détachées

- Boutique

- Malle Louis Vuitton

- Wardrobe 85 1975

- Boite a tout cuir

- Boule a neige - Le groom 2012 G2

- Boule a neige - Aéro 2013 A2

- Mini malle courrier vip 2010

- Ecrin bijoux Epi Rouge

- Vanity boîte a bouteille 1977

- Valise Bisten 70 1977

- Valise President 2009

- Valise président Epi 1987

- Valise President 1966

- Valise President 1978

- Vanity boîte a flacon 1978

- Vanity boîte a flacon M21828 1978

- Vanity boîte a flacon 1968

- Steamer Bag 55 1986

- Steamer Bag 65 1988

- Livre & Accessoire LV

- Malle Goyard

- Malle Moynat

- Malle Louis Vuitton

HOW TO MAINTAIN AND CLEAN YOUR COLLECTOR'S TRUNK

PRECAUTIONS FOR USE: LOUIS VUITTON - GOYARD - MOYNAT

INTRODUCTION

You have recovered a trunk in an attic, you have bought an old trunk that you are exhibiting in your living room. But you don't know how to use and maintain it without damaging it.

Louis Vuitton and Goyard trunks , Moynat in your possession have been made from a rigorous selection of the finest materials, by experienced craftsmen. They have been designed in compliance with the most demanding criteria of quality and know-how which are the hallmarks of luxury houses. Your item is very precious to us and deserves the same care and attention every day. With these tips and a few simple precautions, you will be able to enjoy your collector's trunk for many years to come.

This article is intended to help you maintain your trunk. Louis Vuitton, Goyard and Moynat luxury trunks are fragile and precious. For this reason do not try to play the sorcerer's apprentice at the risk of doing irremediable and irreversible damage to your trunk!

At Malle2luxe, we are proud of our heritage , our know-how and the service we provide to our customers. We will be happy to provide you with additional information or services for your trunks.

CARRYING HANDLE

Whether it's a trunk or a suitcase. If the leather handles are old and original, never take the risk of carrying the luggage by them.

Even if they are in perfect condition, old leather has lost its mechanical properties, so it is important never to stress the leather at the risk of tearing.

On the other hand, if the leather handles have been replaced, if it is a model with a steel or brass handle or if your trunk is recent, there is no problem.

However, be careful not to overload the trunk during transport ...

ENVIRONMENT

It is strongly recommended that you keep your trunks sheltered from the elements. Leather and canvas are sensitive to natural elements: water, fat, oil, perfume, heat, light, excess humidity or drought, so many variations in temperature and hygrometry that will harm your luxury trunk.

Protect it from any prolonged exposure to intense light or heat (direct sunlight, behind a bay window, near a radiator, etc.), these elements may damage the item or cause premature wear.

If it comes into contact with water, wipe it off immediately with a soft, lint-free cloth to avoid the formation of drying marks or blisters.

PROTECT

Some materials can indelibly mark your trunks, wine, candle wax, grease stains. Likewise, repeated contact with a "hard" object may create an abrasion, such as a vase or flowerpot, for example.

If you use your mail trunk or cabin trunk as acoffee table, pedestal table or bedside table, to enjoy it without fear, have a mirror maker make a made- to-measure glass to put on the lid. It will protect from dust and everyday accidents.

STORAGE

If you move, and you store your trunk in a storage unit for longer than two months, do not wrap your trunk in airtight plastic, the materials need to breathe. You can, however, cover it with linen or wrap it in cardboard.

Never store your trunk in a damp place, even for a short time, such as in a cellar.

THE INNER CANVAS

The interior canvas and the quilting are made of cotton and linen canvas glued directly to the wood. These fabrics have not undergone any waterproof or other treatment.

Certain materials can indelibly mark the fabric: ink (markers and pens), oily products (makeup and lipstick), perfume, alcoholic products, shoe polish (from bags or shoe soles). Likewise, repeated contact with raw or dark colored textiles may stain the inner fabric.

Routine maintenance:

Vacuum dust.

Fat stain:

Generously sprinkle the stain with Terre de Sommiers, without rubbing, Leave to act for several hours (one night), rub gently then vacuum to remove the powder.

Bad smell :

Fill a cup with baking soda and leave to act for 4 to 6 days. Repeat the operation as many times as necessary.

If it is a very strong damp smell unfortunately, there will be no solution other than replacing the fabric.

Protective linen:

Use if you store shoes or handbags in your trunk or other waxed accessories. Likewise, if the inside of your trunk is stained and you store white laundry.

Nothing prevents you from putting in the bottom of the trunk a protection like a cloth to protect your trunk or its contents.

THE COATED CANVAS

Cleaning at the exit of the attic:

If you have recovered a trunk in an attic, full of dust, you can use a vacuum cleaner then wipe with a damp cloth with water without any other product (non-dripping at the risk of making stains) and wipe immediately with a dry cloth . Be careful not to wet the leather borders. It is advisable to do this operation as few times as possible at the risk of damaging the canvas. Home remedies such as mink oil, perfume, leather lotions, spray wax, cleaners and other chemicals should not be used on the canvas. The use of these remedies can cause irreversible damage.

THE LEATHER

Unlike the leather handbag (chrome tanned ), the leather of the trunks is vegetable tanned cowhide leather , deeply rooted in the history of travel trunks.

This leather is distinguished by its transparency, which reveals natural marks such as veins and folds, attesting that it has not undergone any treatment. This delicate leather is easily scratched. It will acquire a beautiful amber patina which will be unique to it. This patina, as well as the wear due to its use, are proof of the authenticity of the trunk and of its journey alongside its owner.

In the event of accidental contact with water, dab the leather immediately with an absorbent, clear, lint-free cloth.

It is strongly recommended not to apply a "nourishing milk" which by its fat will stain the leather by trapping the dirt. Solvents, chemicals, or home remedies such as mink oil, saddle leather grease, leather lotions, or substances of any kind should be avoided at all costs.

Routine maintenance:

Just like the old canvas, we recommend dusting it with a soft cloth.

WOODS

The trunks are made of beech wood and poplar. Above all, do not use wood filler, Synthobois or other resin.

They are very practical for tinkering at home but perfectly unsuitable for restoring a luxury or collector's trunk.

Insect presence:

If the wood is wormy, or you detect the presence of an insect , a xylophenetreatment will be necessary.

THE BRASSES

After purchasing your trunk or handbag padlock you will find that the brasses are tarnishing.

The oxidation of brass is unavoidable, it will inevitably turn brown. There is no trick to keeping the brass of your golden trunks forever. The only remedy to keep a golden brass is to polish it regularly with the right product.

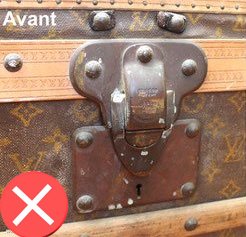

Note: The worse the polishing (for example with a nylon brush), the faster they tarnish and the more complicated or even impossible it is to clean, hence the importance of not buying a brushed trunk.

Above all, do not use a mirror-type household product. Their greasy formula stains leathers and leaves a whitish deposit on fabrics, this damage is irreversible.

Routine maintenance:

Professional brass maintenance kit. We recommend maintenance cleaning every 5 to 8 months depending on the humidity levels of the ambient air.

MAGIC PRODUCT TO CLEAN BRASS

Oxidized brass maintenance kit

Oxidized brass maintenance kit - professional quality

This product is a maintenance product on a brass. Ideal for the maintenance of new or old metals, suitcases, trunks, silverware... For all types of metals: brass, gold, silver, copper, bronze, tin, metal, aluminum...

Quantity and Yield:

- 15 grams allows for 2 to 3 cleanings.

- 45 grams allows for 6 to 9 cleanings. (Offered for the purchase of a suitcase or trunk purchased in our stores)

- 90 grams allows for 12 to 18 cleanings.

- 250 grams allows for 33 to 50 cleanings.

Recommendation: Maintenance cleaning every 4 to 8 months.

Advantage: does not stain (canvas, lozine), non-greasy, ultra-concentrated product, easy to use, ultra-shiny result, lasts a long time.

Does not work on: A brass too oxidized beyond 10 years of oxidation. A scratched brass (for example brushed metallic) or badly polished... read our buying guide

Comprising: an anti-scratch cloth (washable) + a tube of cream + a special corner brush + special cuttable nail cover

Best product for the maintenance of the brasses of your luxury trunks. New very long storage tube (up to 8 years).

89,00 €

TTC, frais de port non compris

Frais de port offerts dans les pays suivants: Autres pays Réduire

- 0,2 kg

- disponible

- 1 à 3 jours de délai de livraison

VIDEO USER GUIDE:

RECOGNIZE A BRASS:

VIDEO GUIDE TO BUYING A LUXURY TRUNK - BRASS

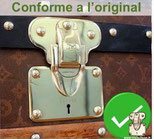

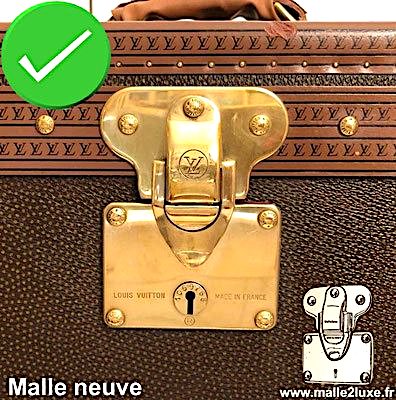

ORIGINAL POLISHED BRASS

Smooth surface, factory mirror polished. Original finish of all Louis Vuitton, Goyard and Moynat luxury trunks since 1870.

NATURAL OXIDATION

Polished brass naturally oxidizes with moisture in the air, taking on an increasingly brown hue. In a humid place oxidation is faster.

BRUSHED BRASS

To remove the oxidation many novices, use a nylon brush which certainly removes the oxidation but the brushing involves a removal of material by abrasive to a certain depth scratching the surfaces definitively, deformed the part, breaks the edges which make the smoothness of the object. The material removed can no longer be added . it's a prejudice, a discount for a collector's trunk.

BRUSHED AND POLISHED BRASS

To hide the brushing disaster, we see more and more polished brass after brushing. The reflections are not uniform, the surfaces remain scratched.

Brushed brasses oxidize much faster than perfectly polished brasses because the surface is porous.

Originally, the luxury trunks have shiny polished brass. The novice initiative to brush brasses is more akin to tunning than restoration. And you can't really call it polishing.

ACID

Products for cleaning brass based on hydrochloric acid eat away at the brass which takes on a red color copper color entering in the composition of the naturally yellow metal. Often brushed and put under acid.

MIROR'S SPOT

Household products of the " magic mirror " type are often used.

The oily formula of these products stains leathers and leaves a whitish deposit on the fabrics, this damage is irreversible on the fabrics.

PERFECTLY POLISHED (IDENTICAL TO THE ORIGINAL):

The better the polished surface, the easier it will be to maintain your brasses and retain their luster and shine. A badly polished brass will not be able to keep the same aspect. If you clean your brasses regularly and the brasses are perfectly polished, you will always have a nice trunk.

Conversely, brushed brass cannot be maintained, it will also oxidize much faster. So be careful.

READ ALSO:

Entretenir sa malle : French page

Copyright © 2008-2024 Malle2luxe Paris. Tous droits réservés.